Polycarbonate

Polycarbonate is a naturally transparent. easily machinable amorphous thermoplastic with very good heat resistance and can be combined with flame retardant materials without significant material degradation.

It can be bent using cold forming and thermoforming techniques, and bonded to itself using chemical bonding adhesives (methylene chloride) to create air-tight strong bonds.

It is commonly used for plastic lenses in eyewear, in medical devices, automotive components, protective gear, greenhouses, Digital Disks (CDs, DVDs, and Blu-ray).

Polycarbonate plastics are engineering plastics in that they are typically used for more capable, robust materials such as in impact resistant “glass-like” surfaces. Never clean Polycarbonate with glass cleaner as this will attack the material over time. Use a mild soap and water to clean Polycarbonate.

Polycarbonate is available in the following grades:

Optical grade , most common type of polycarbonate, comes with protective masking on both sides that should not be removed until fabrication is complete if possible. It is most commonly clear, but colors are available.

Because it is softer than Acrylic it has much greater impact resistance but tends to scratch more easily and will be damaged by direct UV light over time, so if your application is requires exposing the material to direct sunlight, be sure to request UV resistant polycarbonate.

Abrasion Resistant (AR) Because Polycarbonate tends to scratch more easily than Acrylic or glass AR Polycarbonate grades are available; however AR Polycarbonate is not easily be bent or glued after the coating has been applied.

If the fabricated part must be bent, an abrasion resistant coating can be applied after fabrication depending on the size and shape.

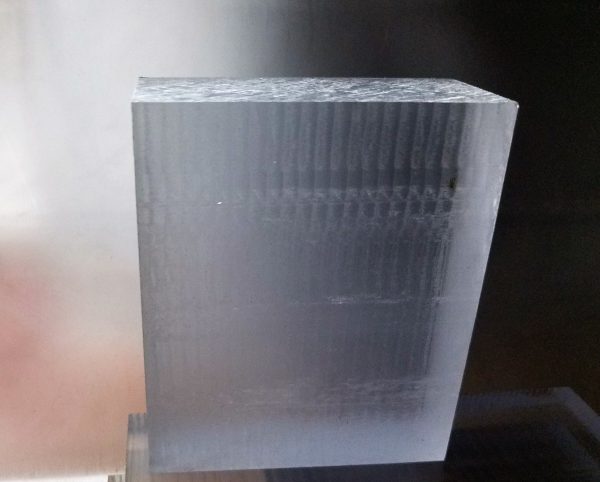

Machine Grade Polycarbonate is an amorphous engineering plastic offering toughness, clarity and high heat- deflection temperatures. It often replaces metal, glass and wood in the automotive, medical, food and beverage, and electronic industries. It is available in Natural, Black, and 20% Glass-reinforced.

BR Polycarbonate has been specifically rated to withstand the impact of gun fire. BR Polycarbonate is made from thinner pieces of polycarbonate laminated together with their extrusion directions turned different ways to take spin off of a bullet.

Available sizes and colors:

Polycarbonate is available in some colors, although a minimum order may be required.

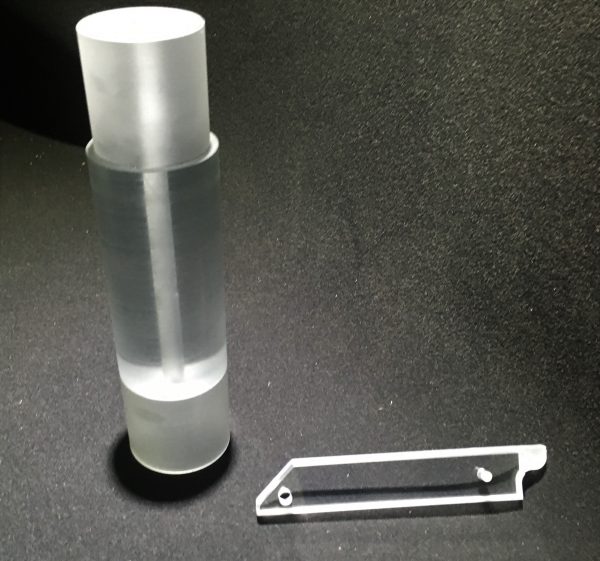

Polycarbonate is available in sheet, round rod and circular tubing stock shapes.

Typical sheet sizes are commonly stocked in 48″ X 96″, 60″ X 96″, 48″ X 120”, and 60″ X 120″.

Some larger sizes are available upon request.

Types:

Clear & Colors

Plate

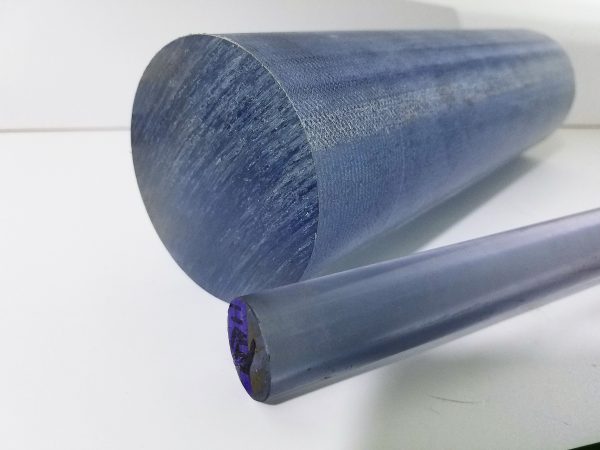

Round Rod

Sheet

Tubing

Film

**Custom Fabricated Guards and Windows